We develop advanced chemistries to

improve your processes and your products.

We engineer effective and high quality cleaners, conformal coatings, and other chemical products to improve the reliability and longevity of electronic products and optimize production throughout.

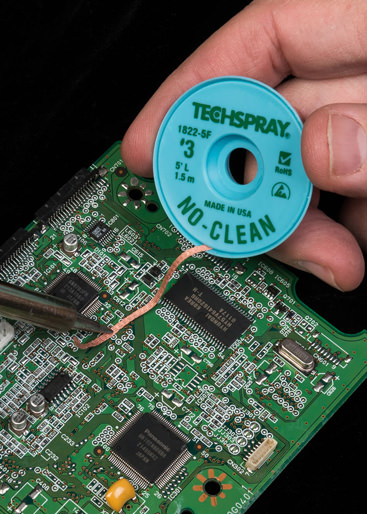

Desoldering Braid

Desoldering Braid

Desoldering braid or desoldering wick is a pre-fluxed copper braid that is used to remove solder allowing components to be replaced and excess solder (e.g., bridging) to be removed. The soldering iron is applied to the wick as it sits on the solder joint, and when both reach the solder's melting point, the flux is activated and, through capillary action from the braided design, solder is drawn up the wick. Techspray wick has been a mainstay at PCB rework, repair and prototyping stations for over 30 years.

Learn More

Flux Remover

Flux Remover

Flux removers (defluxers) remove flux residues and other contaminants left by manufacture, rework, or repair of printed circuit boards. Residues from higher, lead-free temperatures are harder to clean. PWR-4, G3, E-LINE and Precision-V flux removers have been proven very effective at removing fluxes baked on at lead-free temperatures.

Learn More

Wipes

Wipes

Techspray offers a large array of electronic cleaning wipes for a variety of applications, including cleanroom, PCB rework, polishing, and maintenance. A large number of different materials and sizes are available to meet each unique requirement. Techspray offers a range of dry and presaturated wipes to fulfill the needs of your specific application.

Learn More

You did not finish submitting your information to request a sample